What’s more secure than shredding company documents? Why, reducing paper down to its very fibres, then constructing new pieces of paper from the remains, of course.

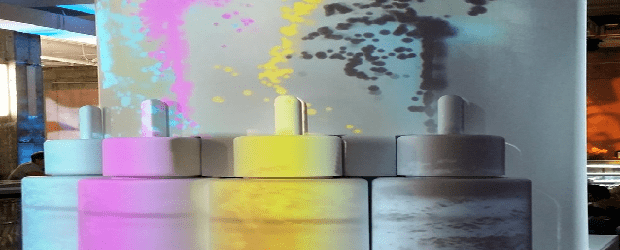

What most would consider an industrial function is now available for the office. Printing giant Epson has unveiled a solution called PaperLab, essentially reducing a paper recycling plant down to a machine the size of a cubicle.

The process, which takes waste paper and pumps out custom-grade sheets, skips the recycling bin and garbage collection completely, not to mention it’s the most secure way possible to destroy documents.

“PaperLab produces the first new sheet of paper in about three minutes of having loaded it with waste paper and pressing the Start button,” Epson claims in an official statement. “The system can produce about 14 A4 sheets per minute and 6,720 sheets in an eight-hour day.”

What’s more, the grade of paper can also be controlled. This can vary from the dimensions, (A4 and A3 were mentioned, although we imagine Letter and other North American sizes to be available) and the thickness, such as business card grade sheets are possible.

Even coloured or scented paper are possible.

The paper-making process usually takes a lot of water, around a cup of water for one single A4 sheet, but not PaperLab. Epson says that a dry process is in place, which means a smaller carbon footprint.

As for converting waste into new paper, Ars Technica reports that an Epson patent describes a process of “crushing and defibrillating paper”, then using air to de-ink the fibres.

From there on, it’s the binding process. In this stage, colour, flame resistance, or even fragrance can be added.

Lastly, during what the company is calling a forming stage, a paper’s thickness and dimensions are determined.

It seems the only thing the machine does not do is print.

Availability in Japan is in 2016, with other regions coming “at a later date.”